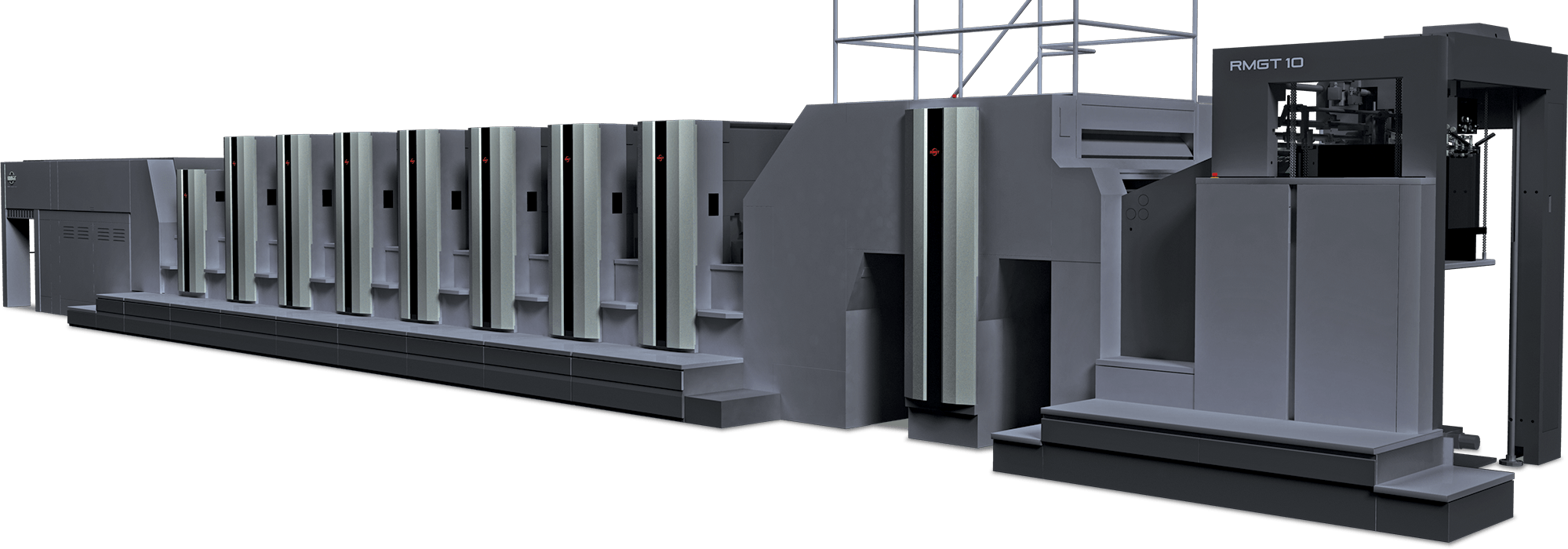

RMGT’s one-of-a-kind tandem perfector packaging press is tripling packaging printers’ success across the globe. With the 1060 TP LX 7/1 CC LD, packages are produced using the technology’s TransLink unit, a triple-diameter transfer system that passes printed sheets from the back side of the press to the front side without turning them over. With this technology, printers can achieve flawless unit-to-unit, side-to-side register and color matching without scratching the surface of the carton.

With automatic feeders, a raised kit, delivery shutters and the PQS-D (I+C+R) Print Quality Control System designed to keep work moving seamlessly from job to job without the need for a press operator to intervene, printers can count on the 1060 TP LX 7/1 CC LD to continually create the perfect package.

| Feeder Section |

|---|

| High speed feeder separator |

| Paper Size preset (separator Front/Back positioning by remote control) |

| Single suction belt type feeder board with Misalignment Prevention function |

| Foreign Substance stopper at feeder board |

| Sheet feeding speed slowdown device |

| Cover below feeder board with limit switch |

| Separator height and front air blast nozzle positioning by remote control |

| Expandable paper guide under separator |

| Electrostatic eliminator |

| Registration Section |

| Photo Electric type Double sheet detector |

| Ultra Sonic type Double sheet detector |

| Roller type paper retainer |

| Side lay preset |

| Torsion bar type swing gripper shaft |

| Front-lay circumferential and cocking register by remote control |

| Pneumatic pull side guide |

| Printing Unit |

| Plate U-Cuts Dimension(Depth): RMGT Standard 11mm |

| Plate U-Cuts Dimension(Lateral): RMGT Standard 780mm |

| Patented doubling prevention system |

| Plate clamp with fan-out adjustment device |

| Stainless steel metalized Plate and Blanket cylinder |

| Chrome plated Impression cylinder |

| Protection cover automatic Open/Close device |

| Bearer wiper |

| Automatic Impression Pressure preset with Plate and Blanket cylinders follow-up Mechanism |

| Torsion bar type gripper Shaft |

| Lubrication-Free grippers bearing |

| Gripper pad Casette type |

| Circumferential, Lateral and Cocking Register adjustment remote control |

| Safety bar between Plate and Blanket cylinder |

| Safety bar between Blanket cylinder and Ink form roller (W) |

| Safety bar between Blanket and Impression cylinder |

| ICP Film for transfer cylinder |

| Fixed sheet guide under transfer cylinder |

| Inking Unit |

| High Precision ink key remote control system (Auto preset inking system) |

| Automatic ink key Zero point adjustment system |

| Variable ink doctor timing remote control |

| Ink Fountain roller rotation remote control |

| Automatic ink roller cleaning device with ink Ductor Blade On/Off remote control |

| Dampening Section |

| On touch On/Off Nipping of DT and DR rollers |

| Water Fountain roller rotation Remote control |

| Water Rider roller (DS) with specialized chrome coating |

| Water Oscillating bridge roller (DB) |

| Multi-Mode dampening system |

| Delivery Section |

| Delivery Drumless cylinder |

| Torsion bar type shadowless chain gripper bar |

| Delivery Jam-up detector |

| Delivery pile thrusting detector |

| Sheet releasing remote control |

| Vaccum slowdown wheel Independent drive |

| Vacuum slowdown wheel |

| Sheet Decurler |

| Automatic lubrication for chain guide |

| Delivery pile automatic lowering |

| Paper Size preset (side Jogger Lateral positioning, Expandable side Jogger, Vacuum slow down wheel Front/Back position and vacuum slow down when suction width presetting) |

| Delivery Saftey area detector |

| Delivery air guide plate |

| Electrostatic eliminator |

| Stack aligner in delivery |

| Operation-Control Section |

| Sequential Start-Up |

| Emergency Impression off at feeder |

| Emergency Impression off at delivery |

| Sequential Impression On |

| Color touch screen at feeder |

| Presetting counter with feeder pump off function |

| High speed Impression On mechanism |

| Active / Satefy Mode Selector Switch (feeder to each unit) |

| Color touch Screen at delivery |

| Multi function Beam (LED) |

| RMGT - Intelligent Press Control |

| Translink |

| Solid type Double-Diameter cylinder Translink unit |

| Paper/Plate Size |

| Paper Thickness Range:0.04~0.6mm |

| Plate Thickness:0.3mm |

| Ink:LED-UV |

| Language:English |

| Safety Regulation:UL |

| The unit for Distance:mm |

| Plate Punch Dimension: RMGT Standard |

| Air Center |

| Second transfer cylinder at Translink unit:Vacuum type |

| Feeder-Registration Section |

| Nonstop Feeder:Automatic |

| Front-Lay Bernoulli |

| Automatic Central Greasing system for feeder board and Register by Cartridge |

| Corrective sheet detector with sheet Clamp device |

| Side-Lay detector:Fiber Sensor type |

| Brush and Rubber roller device (Single bar type) |

| Sheet Circumferential Direction Aligning device |

| Feeder belt Acceleration/Deceleration device: Chain type |

| Printing Unit |

| Simultaneous Full-Automatic Plate Changing system (Simulchanger FPC) 7 COLOR |

| High speed Impression:High speed Impression On (10,000Sph) and Zero Minute Standby of Impression Pressure preset 7 COLOR |

| Support bar for Blanket Change 1 COLOR |

| Automatic Blanket cleaning device:RMGT 7 COLOR |

| Automatic Impression cylinder cleaning device 6 COLOR |

| Inking Unit |

| Ink Clutch : 1st, 2nd, 7th & 8th Printing Units |

| Ink Fountain Roller Independent drive : All Printing Units 1 COLOR |

| Ink Oscillating rollers Dead point positioning remote control: All printing units 7 COLOR |

| Ink Oscillating roller On/Off remote control:All printing units 7 COLOR |

| Automatic cleaning Solvent spray for Oil Based Ink 7 COLOR |

| One Action On/Off Oscillating Ink form roller(W,Z):All printing units 7 COLOR |

| Provision for Ink Oscillating roller Cooling(C1,K1 And K2):All printing units 7 COLOR |

| Dampening Section |

| Dampening Oscillating roller (DR roller):All printing units 7 COLOR |

| Delta type Dampening system:All printing units 7 COLOR |

| Delivery Section |

| Board Insertion guide Automatic Lowering device |

| Delivery Shutter |

| Long Delivery |

| Operation-Control Section |

| PPC Server III Software |

| Press Information Display |

| Special Sheet-for UV-Special Unit |

| Anti Electrostatic Measure:Grade 1 for paper |

| UV Printing 7 SET |

| Interdeck UV Provision_after PU3, PU5, PU7 and PU8 |

| Interdeck UV Provision_before Coating Unit |

| Coating unit |

| Machine Arrangement |

| Press Raise : 450mm |

| Feeder Band Stand:Feeder Band Stand without drive side steps |

| Flip-Up type pile Extraction : Operator side |

| Tray at drive side 7 SET |

| Cover for drive side under foot Step:Selected without Exhaust Fan 7 SET |

| Cover for Operation side foot Step 7 SET |

| Tool Box under Operation side foot Step |

| Air Gun @ Last printing unit Operation side under foot step and feeder |

| Power Supply:60Hz 220V without Transformer |

| Special Order Spec. |

| Chamber type doctor blade coating system with varnish circulator:Harris & Bruno (DUO) |

| Water Spray for BCD |

| Skeleton on the front side |

| PQS-D |

| Auxillary Equipment |

| Rollers - Chameleon X 8 sets + 1 Set Core |

| PPC Server Computer |

| Mitsubishi Remote Access Program |

| Ink Agitator |

| AGT Combi unit |

| X-Rite IntelliTrax Closed Loop Color Spectrophotometer |

| GEW 3 LED Interdeck + 3 CUV EOP |

| Pierry IR |