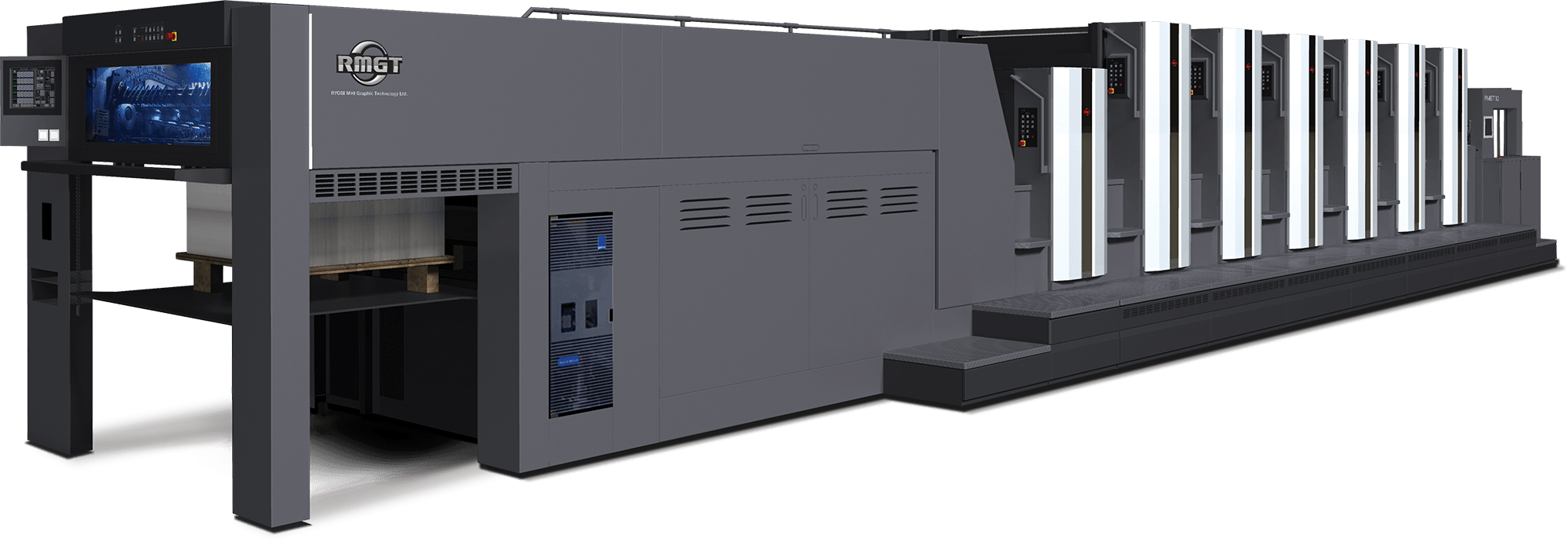

Introducing the RMGT 1060LX Performance Package, a fully loaded press configuration for packaging printers that delivers real-world, measurable productivity improvements to yield more output and better printing performance for your operation.

The Performance Package includes RMGT’s incredible SimulChanger parallel automated plate-changing system that also completes washups at the same time! A new polygon-type vacuum wheel provides a superior vacuum across the entire substrate sheet for unmatched delivery piling performance. Included are improved front-lay and side-lay detectors to accommodate thicker stock up to 1.00 mm.

Fast 17,100 speeds per hour plus Smart Assist Printing™ further drive productivity to even higher levels. Optional high-speed automatic feeder and delivery shutters are available with modest pricing.

| Printing Unit Configurations | 2-12 Units |

|---|---|

| Maximum Sheet Size | 29 1/2" x 41 3/4" |

| Minimum Sheet Size | 14 1/8" x 21 1/4" |

| Sheet Thickness Range | 0.8 - 1.00 and 1.20 mm |

| Maximum Printing Speed | 17,100 IPH |

| Printing Unit | |

|---|---|

| Patented doubling prevention system | |

| Plate clamp with Fan-Out adjustment device | |

| Stainless steel metalized Plate and Blanket cylinder | |

| Chrome plated Impression cylinder | |

| Protection Cover automatic Open/Close device | |

| Bearer Wiper | |

| Automatic Impression Pressure preset with Plate and Blanket cylinders follow-up mechanism | |

| Torsion Bar type gripper shaft | |

| Lubrication-Free grippers bearing | |

| Gripper Pad Casette type | |

| Circumferential, Lateral and Cocking register adjustment remote control | |

| Safety Bar between Plate and Blanket cylinder | |

| Safety Bar between Blanket cylinder and Ink form roller (W) | |

| Safety Bar between Blanket and Impression cylinder | |

| Skeleton type Double Diameter transfer cylinder | |

| Air Shower above Impression cylinder | |

| Air Chamber type sheet guide under transfer cylinder | |

| Gripper Pad Height adjustment device | |

| Skeleton transfer Cylinders Std. | |

| Coater retractable + S - APC plate changers (Optional) | |

| Addition of sheet guide above Impression cylinder | |

| Feeder Section | |

| High speed feeder separator | |

| Paper size preset (Separator Front/Back Positioning by remote control) | |

| Single Suction belt type feeder board with misalignment prevention function | |

| Foreign substance stopper at feeder board | |

| Sheet Feeding speed Slowdown device | |

| Cover Below feeder board with Limit Switch | |

| Separator Height and Front Air Blast Nozzle Positioning by remote control | |

| Expandable paper guide under separator | |

| Fully Automatic Logistic Feeder (Optional) | |

| Electro Static Eliminator | |

| Registration Section | |

| Photo Electric type Double sheet detector | |

| Ultra Sonic type Double sheet detector | |

| Roller type paper retainer | |

| Side Lay preset | |

| Torsion Bar type Swing gripper shaft | |

| Front-Lay Circumferential and Cocking register by remote control | |

| Pneumatic pull side guide | |

| Inking Unit | |

| High Precision Ink Key remote control system (Auto preset Inking system) | |

| Automatic Ink key zero point adjustment system | |

| Variable Ink Doctor timing remote control | |

| Ink Fountain roller rotation remote control | |

| Automatic Ink roller cleaning device with Ink ductor Blade On/Off remote control | |

| Dampening Section | |

| On Touch On/Off nipping of DT and DR rollers | |

| Water fountain roller rotation remote control | |

| Water rider roller (DS) with specialized chrome coating | |

| Water oscillating bridge roller (DB) | |

| Multi-Mode dampening system | |

| Delivery Section | |

| Highspeed package spec. with Polygon wheel in Delivery (STD.) | |

| Delivery drumless cylinder | |

| Torsion bar type shadowless chain gripper Bar | |

| Delivery jam-up detector | |

| Delivery pile thrusting detector | |

| Sheet releasing remote control | |

| Vaccum slowdown wheel with independent drive | |

| Sheet decurler | |

| Automatic lubrication for chain guide | |

| Delivery pile automatic lowering | |

| Paper size preset (Side jogger lateral positioning, Expandable side jogger, vacuum slow down wheel Front/Back position and vacuum slow down wheel suction width presetting) | |

| Delivery Saftey Area detector | |

| Delivery Air guide plate | |

| Electro Static Eliminator | |

| Stack Aligner In delivery | |

| Operation-Control Section | |

| Sequential start-up | |

| Emergency Impression Off at feeder | |

| Emergency Impression Off at delivery | |

| Sequential Impression On | |

| Color touch screen at feeder | |

| Presetting counter with feeder Pump Off function | |

| High speed Impression On Mechanism | |

| Active / Safety mode selector switch (Feeder to each unit) | |

| Color touch screen at delivery | |

| Multi function beam (LED) | |

| RMGT - Intelligent press control | |

| Paper/Plate Size | |

| Paper Thickness Range:0.04~0.8mm 1.00 mm and 1.20 mm. | |

| Plate Thickness:0.3mm | |

| Ink:Oil Based | |

| Op Varnish:Selected (All Printing Units) | |

| Language:English | |

| Safety Regulation:UL | |

| The unit for Distance:mm | |

| Plate punch Dimension: RMGT Standard | |

| Feeder-Registration Section | |

| Front-Lay Bernoulli | |

| Automatic central greasing system for feeder board and register by cartridge | |

| Corrective sheet detector with sheet clamp device | |

| Side-Lay detector | |

| Brush and Rubber roller device (Single Bar type) | |

| Feeder belt acceleration/deceleration device | |

| Printing Unit | |

| Plate Changer :Full FPC, SMX and S-APC | |

| Support bar for blanket change | |

| Automatic Blanket cleaning device | |

| Inking Unit | |

| Ink Clutch:On any two Printing Units (STD) | |

| Ink Fountain roller Independent drive | |

| Ink Oscillating rollers Dead point positioning remote control | |

| Ink Oscillating Roller On/Off remote control | |

| Dampening Section | |

| Dampening Oscillating roller (DR Roller) | |

| Delta type Dampening system | |

| Delivery Section | |

| Cleaning brush for Chain gripper | |

| Board Insertion guide automatic lowering device | |

| Powder Spray (Grafix Megatronic S-Hep) | |

| Long Delivery | |

| Delivery Shutter (Optional) | |

| Operation-Control Section | |

| PPC Server III Software | |

| Press Information EDGE with PQS D-I-R - SAP (Optional) | |

| Press Information Display | |

| Special sheet for UV-Special Unit | |

| Anti Scratching Measure:Grade 1 for Metalized paper, Mirror Coating, Matt Coating, Card paper and Straight Printing | |

| Air Blow under Swing:Selected | |

| UV Printing:UV Provision <= Including Ink Mist Collector, Etc. | |

| Interdeck Provision : Selected (All Printing Units) | |

| Machine Arrangement | |

| Press Raise:450mm | |

| Feeder Band Stand:Addition of Drive side Steps | |

| Delivery Band Stand:Delivery Band Stand_Not Selected (Flip-Up type Pile Extraction)_Selected | |

| Direction of delivery Pile Extraction:Operation side | |

| Others | |

| Tray at Drive side | |

| Cover for Drive side under foot step | |

| Cover for Operation side foot step | |

| Tool Box under Operation side foot step | |

| Power Supply:60Hz 220V without Transformer | |

| X-Rite Interface | |

| 17,100 SPH | |

| UV-Prep at EOP | |

| BW water spray (RMGT) | |

| Auxilliary Equipment | |

| Rollers (Bottcher) | |

| Remote Access Program | |

| H&B Anilox Coater - Aqueous/UV | |

| H&B Spare Anilox roller | |

| AGT Combi Unit | |

| X-Rite Intellitrax Closed Loop Color Spectrophotometer | |

| Air Center Cabinets |

Detect imperfected sheets fast with the Print Quality Control System (PQS-D) from RM Machinery. Available with every RMGT press, the PQS-D automatically monitors critical registration and density via a CCD camera and makes adjustments on the fly.

This simultaneous plate cylinder repositioning system targets the time-consuming plate-changing steps in press makereadies.

PCS-N, RMGT’s intelligent automated press control system, is a vital link in the digital chain.

Energy-conserving, long-life LED-UV curing system instantly dries printed sheets using light-emitting diodes.